Product

Pipes

Our product range includes a wide range of carbon steel pipes & tubes, Alloy steel pipes & tubes and stainless steel pipes & tubes.

Stainless steel pipes and tubes

Seamless, Welded, ERW, Semi Welded & EFW

Products

ERW Pipes & Tubes

ERW (Electrical Resistance Welding) pipes are manufactured by cold forming of steel coil into a round cylindrical shape. In the initial times it was done with the low frequency A.C. current to heat the edges. Pipes and Tubes as per specifications of IS, BS, API, ASTM, DIN, IBR which conforms to the various international standards. ERW steel pipes and tubes are used in various engineering purposes, fencing, scaffolding, line pipes etc. ERW steel pipes and tube are available in various qualities, wall thicknesses, finished and diameter.

Major applications

- Water pipelines

- Agriculture & irrigation (Water mains, industrial water pipe lines, plant piping, deep tube-wells & casing pipes, sewerage piping)

- Gas pipe lines

- LPG and other non-toxic gas lines

Seamless Pipes & Tubes

Seamless pipe as the name suggests is a pipe without a seam or a weld-joint in contrast to Seam or Welded pipe. In a Seam or Welded pipe, the seam or the weld-joint is the weaker part of the pipe limiting the strength of the pipe to the strength of the weld-joint. Whereas the seamless pipe does not have any such joint and thus has uniform structure & strength all over the pipe body. Thus the seamless pipe can withstand higher pressure, higher temperature, higher mechanical stress & corrosive atmosphere.

- Oil & Gas, Refinery

- Petrochemical, Chemical

- Fertilizer, Power

- Automotive, Bearing

- Mechanical & Structural applications

Stainless Steel, Carbon Steel, Alloy steel & Special Steel in form of ERW & Seamless Pipes, Sheets, Plates & Coils, Pipe Fittings, Round Bar, Flats, Angles, Channel and Wire, all under one roof to meet the clients requirement.

- API 5L - GRADE B PSL1, X42 PSL1, X46 PSL1, X52 PSL1, X56 PSL1, PSL1, X65 PSL1, X70 PSL1, X80 PSL1, X100PSL1

- API 5L - GRADE B PSL2, X42 PSL2, X46 PSL2, X52 PSL2, X56 PSL2, PSL2, X65 PSL2, X70 PSL2, X80 PSL2, X100PSL2

- ASTM A671/A671M GRADE CA 55, CB 60, CB 65, CB 70, CC 60, CC 65, CC 70

- ASTM A672/A672M GRADE A 45, A450, A55, B60, B65, B70, C55, C60,C65, C70

- ASTM A53/A53M GRADE A & B IN TYPE E,F & S.

- ASTM A106/A106M GRADE A,B & C.

- ASTM A333/A333M GRADE 1 & 6.

- ASTM A335 GRADE P1, P5, P11, P12, P91

- API 5L Grade B PSL1 Line Pipes

- API 5L Grade B PSL2 Line Pipes

- API 5L Grade B PSL1 Sour Service Line Pipes

- API 5L Grade B PSL2 Sour Service Line Pipes

- API 5L Grade B PSL1 NACE MR-0175 Line Pipes

.png)

Pipe Fitting

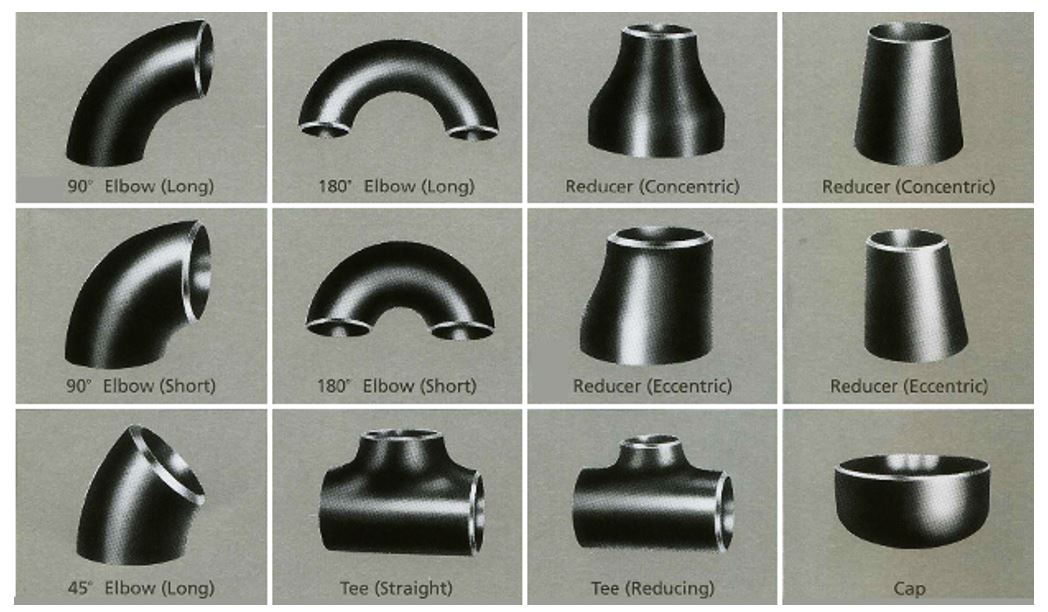

Buttweld Fittings

- 90° Long Radius Elbow

- 90° Short Radius Elbow

- 45° Long Radius Elbow

- 45° Short Radius Elbow

- 180° Long Radius Elbow

- 180° Short Radius Elbow

- 1D Elbows

- 1.5D Elbows

- 3D Elbows

- 5D Elbows

- Seamless Buttwelding 45° and 90° Elbows

- Seamless Buttwelding 180° Returns

- Straight Tees and Crosses

- Equal Tee

- Reducing Tee

- Equal Cross

- Reducing Cross

- Reducers

- Concentric Reducers

- Eccentric Reducers

- Stub End

- Lap Joint Stub End

Forged Threaded Fittings

- 90° Elbow

- 45° Elbow

- Tee

- Cross

- Expander

- Reducer

- Full Coupling

- Half Coupling

- Pipe Cap

- Hexa Head Bushing

- Hex Head Plug

- Street Elbow

- Bull Plug

- Boss

- Swage Nipple

- Pipe Nipple

- Adapter

- Union ( Male / Female)

- Branch Outlet

- 90° Elbow Outlet

- 45° Lateral Tee

- Lateral Outlet

- Nipple Branch Outlet

Olets

- Weldolet

- Sockolet

- Threadolet

- Nipolet

- Elbolet

- Threaded Elbolet

- Socket Weld Elbolet

- Sweepolet

- Insert weldolet

- Brazolet

- Coupolet

- Flexolet buttweld

- Flexolet Socket Weld

- Flexolet Threaded

- Nipo Flange

Socketweld Fittings

- 90° Elbow

- 45° Elbow

- Tee

- Cross

- 1D Elbows

- 1.5D Elbows

- 3D Elbows

- 5D Elbows

- Full Coupling

- Half Coupling

- Pipe Cap

- Boss

- Reducer Insert

- Pipe Nipple

- Branch Outlet

- 90° Elbow Outlet

- 45° Lateral Tee

- Lateral Outlet

- Socket Weld Reducers

- Socket Weld Concentric Reducers

- Socket Weld Eccentric Reducers

- Socket Weld Equal Tee

Flange

Range: ½” (15 NB) to 48” (1200NB) INDUSTRIAL FLANGES

Type of Flange

- ANSI/ASME FORGED FLANGES

- MSS-SP-44 FLANGES/ANSI B 16.47 SERIES A

- API TYPE 6A - RTJ Face Flanges

- API-605 FLANGES/ANSI B 16.47 SERIES B

- A.G.A. ORIFICE UNIONS - Furnished with or without Hardware.

- ASME BOILER CODE FLANGES

- CL. 125 LIGHTWEIGHT FLANGES - For low pressure applications.

- PLATE FLANGES - From 1/4" thru 8" Thick, Including AWWA C-207,and all other

- special designs.

- ANSI LONG WELDNECKS & SPECIAL BODY CONNECTORS, HB, E, I1, I2, I3 and CUSTOM

- STUDDING OUTLETS (pad flanges) – flat bottom or radiused to fit

- SPECTACLE BLINDS - (line blinds, paddle spacers/blinds)

- DIN FLANGES

- JIS FLANGES

- Special Ring Flanges

Materials of Flange:

- CARBON STEEL - ASTM/ASME SA-105, A-350 LF-2, LF-3, A694, SA-516-70,

- CHROME ALLOYS - A-182-F-1, F-5, F-6, F-9, F-91, F-11, F-12, F-22

- STAINLESS STEEL - A-182 - F-304, Dual Grade 304/304L, Dual Grade 316/316L, 316, 304H, Dual Grade 304/304H, Dual Grade 316/316H, 316H, 309, 310, 317L, 321, 347, 347H, 904L,

- Alloy 20, many other H grades

- ALUMINUM - 3003, 6061, 5083 and other grades upon request.

- HASTALLOY - B-2, C-276, G, X, C-22

- INCONEL - 600, 601, 625, 718

- INCOLLOY - 800, 825, 800H, 800HT

- MONEL - 400

- COPPER - 90/10 (C70600), 70/30 (C71500)

- Duplex – F51/2205, F53/2507

Customized Flanges : Customized flanges can be machined from customers’ drawings to any special requirements that are needed.

STAINLESS STEEL FLANGE

ASTM / ASME SA 182 F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347

Range: 15 NB upto 600 NB in 150 LBS, 300 LBS, 400 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS / TABLE 2.5, TABLE 6, TABLE 10, TABLE 16, TABLE 25, TABLE 40, TABLE 64, TABLE 160, TABLE 320, TABLE 400

Form: Slip on, socket weld, blind, lapped, screwed, weld neck, reducing, spectacle, slip on boss, plate, plate blank, screwed boss